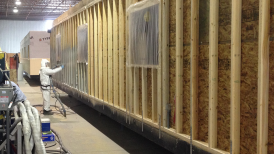

Pinnacle has a full selection of products and can be incorporated into manufacturing processes where there is a need for an insulation or protective coating. Pinnacle has installed spray systems into factories that produce all manner of items.

The fact that our fast set coatings and foam are touch dry in 5 to 30 seconds means that the sprayed item can be handled almost immediately, unlike other products which require time to dry. The sprayed item can be then be transferred to the next stage of production allowing for the next item to be coated.

Most of our products are 100% solids and contain NO CFC’s, NO VOC’s and are SOLVENT FREE.

If you currently have a manufacturing process that requires an insulation or protective coating to be applied to the items produced, whether it’s for protection against impact, abrasion, corrosion or just for cosmetic purposes then Pinnacle may have the solution for you.

Benefits

Reduces maintenance costs, repairs and equipment downtime

Increases personnel safety and productivity

Adds years of life to any surface

Shields against abrasion, impacts and abuse from the elements

Protection against corrosion and rust

Reduced vibration and noise

Easy cleaning with low maintenance

Lower production costs than traditional coating solutions

Flexible formulations adhere to almost any substrate regardless of shape or size and can expand with thermal expansion/contraction changes

Typical Applications

Speaker Manufactures

Potable Water Applications

Blast Mats, Barricades

Automotive Parts

Fountain Insets

Light Plant and Machinery

Metal Fabricators

Film Set Props

Storage Bins, Tanks

Outdoor Equipment

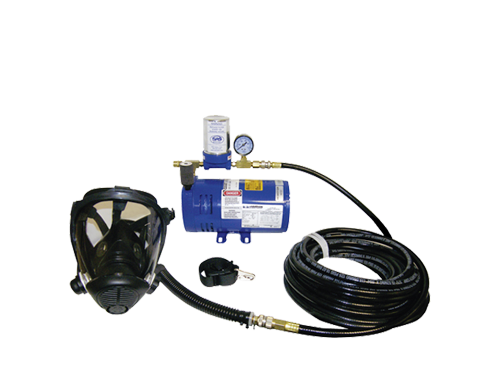

Equipment & Supplies

Pinnacle’s complete line of equipment gives you the reliable performance your company demands. Don’t settle for anything less.