Open & Closed Cell Spray Foam

Polyurethane spray foam is an extremely versatile material that is available in a variety of final physical properties and densities, making it necessary for the applicator to have an understanding of these differences in order to choose the spray foam system that is best suited for the particular application.

Spray Foam used for residential or commercial insulation is categorized into two types, “open-cell” or “closed-cell”. Open cell is lightweight foam that is flexible, and an excellent air barrier. With open cell foam the tiny cells of the foam are not completely closed and air fills all of the “open” space inside the material. Closed cell foam is higher density foam, and a moisture barrier when applied at a thickness of 50mm or more. Closed-cell foam incorporates an insulating gas that is retained within the cells (“blowing agent”), which leads to the highly efficient insulating properties of the material.

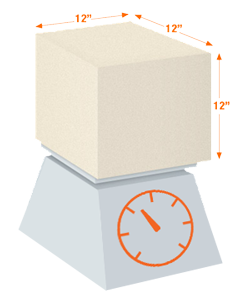

Foam Density

Density is measured by weighing one solid cubic foot of foam material. Density equals how many pounds per cubic foot it weighs. So when we say two-pound density foam, it means that a piece of foam 12″w x 12″l x 12″h will weigh 2 lbs.

Open cell foams for insulation typically weigh in at 0.4 to 0.7 lb./cu. ft.

Closed cell foam for insulation applications range in density from 1.7 lb./cu. ft. to 2.6 lb./cu. ft.

Closed cell foam for roofing applications typically use a 2.5 to 3.0+ lb./cu. ft. to support traffic and loads better.

The higher the density of the foam, the heavier, or stronger it becomes. Some polyurethane foams are molded into decorative interior molding and painted or stained for a simulated wood effect. These “higher density” foams are typically in the 30 lb./cu. ft. to 40 lb./cu. ft. density range.

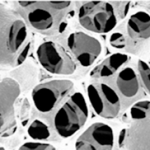

Open Cell Spray Foam Insulation

Open-Cell insulation foam is a liquid which is spray-applied. The liquid turns to foam within two to three seconds and expands in volume about 100 times. With Open-Cell foam the tiny cells of the foam are not completely closed. They are broken and air fills all of the “open” space inside the material.

Open-Cell insulation foam is a liquid which is spray-applied. The liquid turns to foam within two to three seconds and expands in volume about 100 times. With Open-Cell foam the tiny cells of the foam are not completely closed. They are broken and air fills all of the “open” space inside the material.

Open-Cell foam fills every crack and crevice and thus provides a perfect air seal for the building envelope. This foam has a soft, almost spongy feel to it because of its open cell structure.

Advantages of open-cell foam include cost effectiveness and its ability to be applied at 6 to 8 inch thickness in one single pass. Open-cell foam has an R-value around 3.7 per inch and typically uses water as the blowing agent. Disadvantages of open-cell foam compared to closed-cell foam include its lower R-value, less strength, and its lack of vapor barrier qualities.

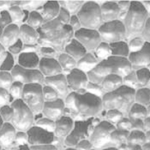

Closed Cell Spray Foam Insulation

The higher density Closed-Cell spray foam insulation is a spray-applied liquid just like the Open-Cell foam, except that it only expands about 40 times its volume. Closed-cell foam differs in that all of its tiny foam cells are closed and packed together. They are filled with a gas that helps the foam rise and expand and become a greater insulator.

The higher density Closed-Cell spray foam insulation is a spray-applied liquid just like the Open-Cell foam, except that it only expands about 40 times its volume. Closed-cell foam differs in that all of its tiny foam cells are closed and packed together. They are filled with a gas that helps the foam rise and expand and become a greater insulator.

It seals so tightly that it may qualify as a vapor barrier. Due to its higher density, this type of foam feels stiffer and actually adds structural value to the home or building.

The advantages of closed-cell foam include its strength, higher R-value of 6.0 per inch, and its resistance to the leakage of air or water vapour. Disadvantages of closed-cell foam include its greater expense due to the higher density and therefore the requirement of more material.