Lower Energy Consumption

![]() Whether it is whole home insulation, retro-fitting an existing attic or spraying foam in a basement, all solutions have a dramatic effect on your monthly energy consumption.

Whether it is whole home insulation, retro-fitting an existing attic or spraying foam in a basement, all solutions have a dramatic effect on your monthly energy consumption.

Typical applications may see a result of 50% reduction in heating and cooling costs. Important to note, is not only will a great reduction in energy consumption be produced, a vast reduction in your carbon emissions will also be seen in correspondence with the reduction of energy usage.

Moisture Control

![]() In walls or ceilings insulated with porous insulating materials such as fiberglass, a poly vapor retarder is usually installed on the warm side of the insulation (that is, on the inside in heating climates and on the outside in cooling climates) to prevent condensed moisture from wetting the insulation. But because foam itself is resistant to water vapor, it may be possible to omit this added step. The question of whether to install a separate vapor retarder will depend partly on the specific foam you choose and partly on your local building inspector.

In walls or ceilings insulated with porous insulating materials such as fiberglass, a poly vapor retarder is usually installed on the warm side of the insulation (that is, on the inside in heating climates and on the outside in cooling climates) to prevent condensed moisture from wetting the insulation. But because foam itself is resistant to water vapor, it may be possible to omit this added step. The question of whether to install a separate vapor retarder will depend partly on the specific foam you choose and partly on your local building inspector.

It’s an ideal insulating material for mixed climates, where the warm and cold sides of the building envelope reverse during the year. During the heating season, the vapor retarder belongs on the inside of the wall, but when the air conditioning kicks on during the summer, it belongs on the outside. This is a practical impossibility with permeable insulating materials. But because foam is uniformly solid, it resists the passage of vapor equally well in either direction.

Sound Control

![]() Sound waves are transmitted by different media, including air. The most drastic noise dampening occurs when the home or building is completely airtight.

Sound waves are transmitted by different media, including air. The most drastic noise dampening occurs when the home or building is completely airtight.

The super soft nature of open cell foam insulation not only provides an extraordinary air seal but also absorbs secondary reverberations for excellent sound dampening properties.

Air Infiltration

![]() There are important differences to note between spray foam insulation systems and conventional insulation materials. The primary characteristic is that spray foam does not sag, settle, or shrink over time. Spray foam insulation is spray applied to fill cavities of any shape offering a continuous air barrier and it stays in place.

There are important differences to note between spray foam insulation systems and conventional insulation materials. The primary characteristic is that spray foam does not sag, settle, or shrink over time. Spray foam insulation is spray applied to fill cavities of any shape offering a continuous air barrier and it stays in place.

Because conventional insulation does not directly bond to the substrate, the chance of the insulation material sagging overtime is high. If conventional insulation is not properly installed around irregular framing areas or it sags in the wall cavity, voids of 1-2% can lower the effective R-value of traditional insulation materials by 25-40%.

Environmental Benefits

![]() Spray foam insulation may be the best thing for the environment in an array of environmentally-friendly products. It emits no CO₂ of its own while it reduces heating and cooling related emissions by about 50% for new constructions and by even more in certain retrofit situations. Foam insulation will last for the life of the building, and will deliver peak performance. No formaldehyde, no ozone-depleting ingredients and no emissions of any kind – environmentally friendly.

Spray foam insulation may be the best thing for the environment in an array of environmentally-friendly products. It emits no CO₂ of its own while it reduces heating and cooling related emissions by about 50% for new constructions and by even more in certain retrofit situations. Foam insulation will last for the life of the building, and will deliver peak performance. No formaldehyde, no ozone-depleting ingredients and no emissions of any kind – environmentally friendly.

Indoor Air Quality

![]() According to the EPA (Environmental Protection Agency), indoor air quality is a major concern. Spray foam insulation battles this problem in two ways. Foam insulation is devoid of emissions and contaminants. It also improves the situation by nearly eliminating all unwanted moisture intrusion and related mold issues. This is also good news for people suffering from asthma, allergies and other respiratory ailments.

According to the EPA (Environmental Protection Agency), indoor air quality is a major concern. Spray foam insulation battles this problem in two ways. Foam insulation is devoid of emissions and contaminants. It also improves the situation by nearly eliminating all unwanted moisture intrusion and related mold issues. This is also good news for people suffering from asthma, allergies and other respiratory ailments.

Unlike more traditional methods of insulation in today’s markets, spray foam insulation is free of all HFAs, HCFCs, HFCs, and formaldehyde. Once spray foam has cured and is in place, the final product is chemically dead and contains no health risks.

Lower The Operational Costs of a Home

The primary reason why many home buyers baulk at spray foam is the difference in price from conventional fiberglass. While the initial investment for spray foam is higher than fiberglass, the cost savings provided by having the home insulated with spray foam along with the many additional benefits make it a worthwhile investment.

Lets take a look at the impact it has on the operational costs of a home. There is almost no other product that a homeowner can buy that provides the return on investment of spray foam insulation. The following is an example of how your customers will save money with foam.

Case in point:

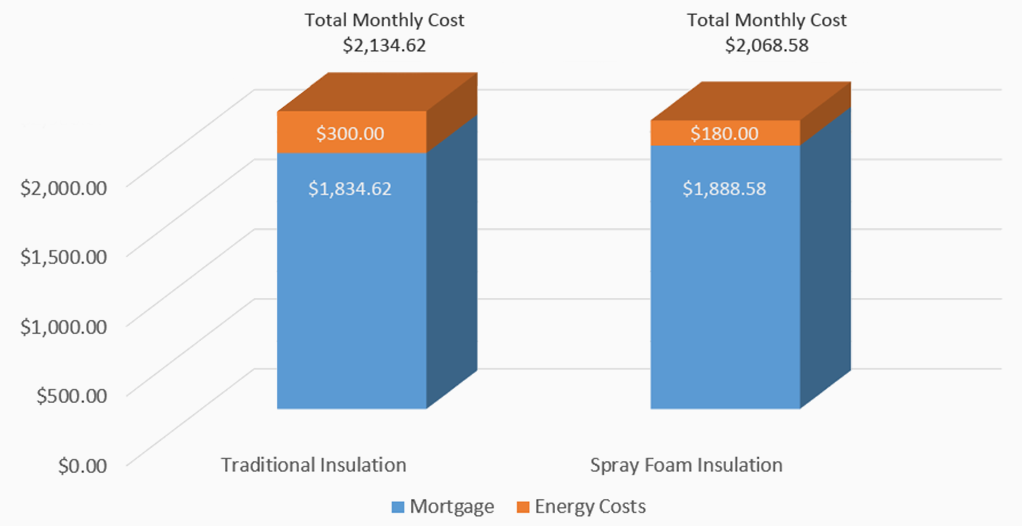

A homeowner buys a $300,000 home. Let’s assume that to insulate with fiberglass is going to cost $6,000, and to insulate with spray foam will cost $15,000. In the example these costs have been added to the mortgage to show the monthly difference in payments.

With fiberglass insulation the $306,000 mortgage at 6% for 30 years the payments would be $1,834.62 with the monthly energy costs estimated at $300.

If the homeowner chose to install spray foam insulation their mortgage would have increased to $315,000. At the same 6% for 30 years the payments would be $1,888.58 but energy costs have dropped to $180 (In this example we are assuming a conservative 40% energy reduction by using spray foam over fiberglass).

This means that choosing spray foam reduces the total home operation cost by $65.94 a month or $23,738.40 over the life of a 30 year loan.

Energy efficient homes produce immediate positive cash flow for home buyers because the reduction in monthly bills more than offsets the higher monthly mortgage payment needed to finance such investments.