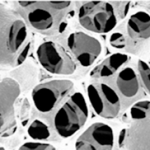

Open Cell Foam

Open Cell Spray Foam Insulation is a high yield, high quality product that is essential for today’s rising energy costs. One of the advantages that the lower density provides is a more economical yield, since foam density is directly related to yield (lower density = higher yield). Although the R-value of open-cell foam is about half that of closed-cell foams, these products can still provide excellent thermal insulating and air barrier properties.

Open Cell Spray Foam Insulation is a high yield, high quality product that is essential for today’s rising energy costs. One of the advantages that the lower density provides is a more economical yield, since foam density is directly related to yield (lower density = higher yield). Although the R-value of open-cell foam is about half that of closed-cell foams, these products can still provide excellent thermal insulating and air barrier properties.

Provides dramatic savings in heating & cooling costs

Creates a seamless air barrier

Helps to eliminate the growth of mold

Breathes (very slowly, still is an effective air barrier)

Provides excellent noise reduction due to softness

Lowest cost among different foam types

Open cell spray foam insulation is spray-applied as a liquid, expanding 100 times its volume. It cures within seconds to fill every crack and gap. Compared with traditional insulation, spray foam provides up to 50% energy savings due to its inherent, perfect air seal.

This type of insulation material uses open-cell technology, which offers the best R-value/cost ratio. The high energy savings are the result of very low ACH (air changes per hour) ratings. Open-cell spray foam insulation performs as an effective air barrier but does not qualify as a vapor barrier. Building scientists are divided as to whether vapor barriers are always needed or not.

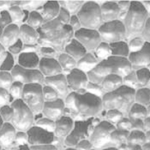

Closed Cell Foam

Closed cell polyurethane spray foam is among the most efficient insulating materials commercially available, with R-values double that of other insulation materials. Closed-cell polyurethane foams are usually characterized by their rigidity and strength, in addition to the high R-Value. The closed-cell nature of this foam provides for a highly effective air barrier, low moisture vapor permeability, and excellent resistance to water.

Closed cell polyurethane spray foam is among the most efficient insulating materials commercially available, with R-values double that of other insulation materials. Closed-cell polyurethane foams are usually characterized by their rigidity and strength, in addition to the high R-Value. The closed-cell nature of this foam provides for a highly effective air barrier, low moisture vapor permeability, and excellent resistance to water.

Achieves an R-Value double that of other insulation materials

Is a moisture barrier when applied at a thickness of 50mm or more

Provides dramatic savings in heating & cooling costs

Suitable for exterior and below grade applications as it rejects water

Creates a seamless air barrier

Prevents the growth of mold

Closed cell spray foam insulation is applied as a liquid expanding 40 times its volume in a matter of seconds. Closed cell spray foam is a higher density foam and therefore feels more stiff than lower density foams. In addition, the closed-cell nature of this foam provides for a highly effective air barrier, low moisture vapor permeability (often referred to as the “Perm” rating), and excellent resistance to water.

Highest cost/output ratio of all the various foam types, closed-cell polyurethane foams are usually characterized by their rigidity and strength, in addition to the high R-Value. Also, studies show that wall racking strength can by doubled or tripled when closed cell foam is applied.