BULLDOGi Spray Rig

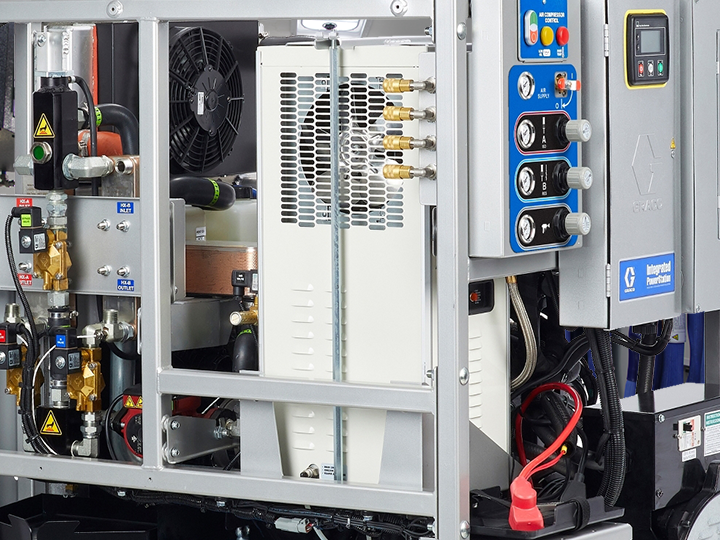

The BULLDOGi spray rig features Graco’s latest spray system, the integrated PowerStation that uses the heat from the diesel engine to help heat the A and B materials in the Reactor. This eliminates or significantly reduces the need for electrical heaters – reducing your fuel costs.

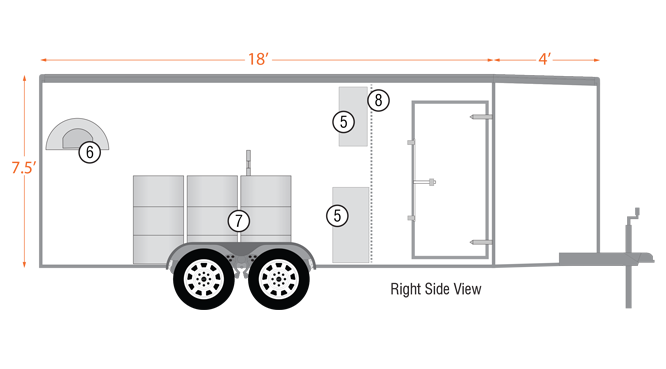

The BULLDOGi delivers turn-key function and ample size through its 18’ V-nose shell. Outfitted with a 20 CFM Hydrovane rotary compressor, refrigerated compressed air dryer, two Graco T-3 or E1 transfer pumps, Graco Fusion PC spray gun, up to 320 ft. of heated hose and space for six 55 gallon drums of material this rig can handle a wide range of applications including spray foam insulation and polyurea protective coatings.

This innovative design is the first heat-as-you-go application equipment that uses co-generation technology to improve spraying performance and save diesel fuel.

Smaller Generator Saves Fuel

The significant fuel savings and financial benefits of the integrated PowerStation our BULLDOGi rig is built around clearly shows the power of Graco’s products.

22 kW

Diesel Generator

20 cfm

Air Compressor

320 ft

Max Hose Length

30 lb

Max Output/min

12,000 lb

GVWR

18′ x 8′

V-nose Trailer

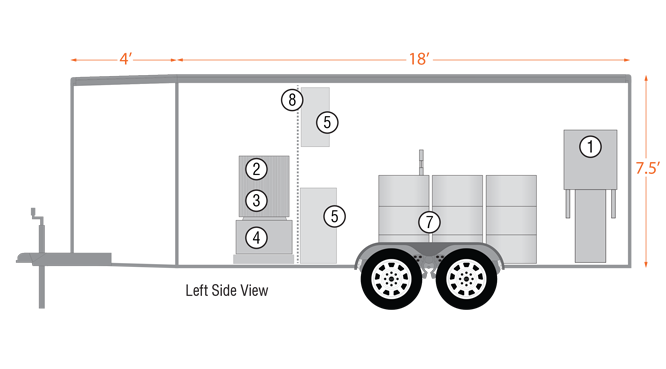

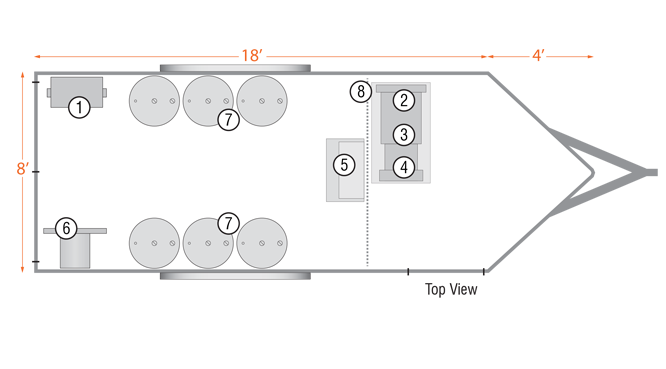

Spray Rig Layout

Step into the spray foam and coatings industry and step up to success with the BULLDOGi spray rig from Pinnacle.

The BULLDOGi comes complete with your choice of Graco Reactor 2 H-Series or Reactor 3 E-Series spray machine. A complete system for polyurethane foam or polyurea applications.

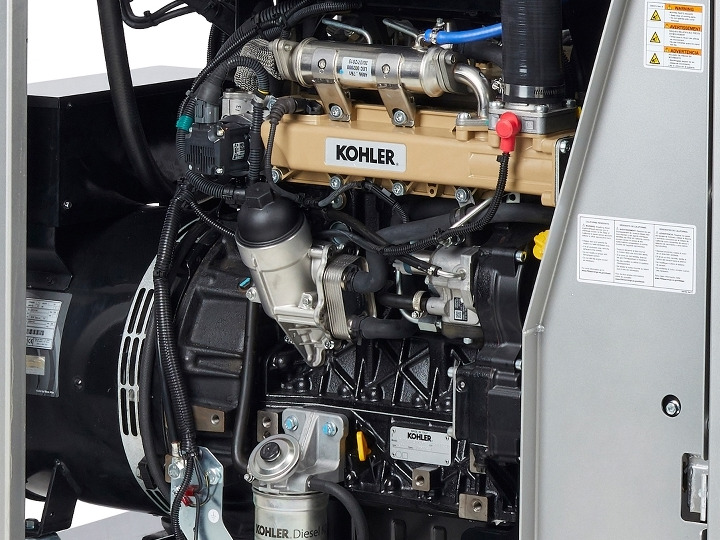

The Integrated PowerStation combines a diesel generator, Hydrovane rotary compressor and refrigerated air dryer into one package. The system’s smaller 22 kw generator uses less fuel than a standard 40 kw generator. You benefit from an annual fuel savings on average of $7,000.1

- Graco Reactor Spray Machine

- 22 kW Diesel Generator

- 20 CFM Hydrovane compressor

- Compressed Air Dryer

- Wall Mount Storage Cabinet

- Hose Rack

- E-Track and Ratchet Straps for Drums

- Divider wall

Equipment Details

- Graco Reactor E-30, E-XP2, H-30 or H-XP2 Spray Machine2

- Flow Meters verify material is applied on-ratio3

- Graco Fusion PC Spray Gun

- Graco Heated Hose, Up To 300 ft.4

- Graco Heated Whip Hose, 20 ft.4

- Graco Expanding Blade Drum Mixer

- Graco T3 or E1 Transfer Pumps

- Transfer Pump Plumbing Package

- Desiccant Cartridge Kit with Drum Mounts

- 22 kW, Single Phase Diesel Generator

- Muffler, Exhaust, Fuel Cell

- Dual Deep Cycle Batteries

- Shore Powered Battery Tender

- Shore Power Plug with 50 ft Extension Cord

- Integrated Electrical Panel and Wiring

- 20 CFM, Constant Run, Hydrovane Compressor5

- Refrigerated Compressed Air Dryer

- Air Supply Piping

- Floor Mount Storage Cabinet with Work Bench

- Wall Mount Storage Cabinet

- E-Track and Ratchet Straps for Drums

- Hose Rack

- 55 Gallon Drum Dolly

- Drum Wrench

- Blow Gun

Trailer Details

- 18 x 8 ft. Extra Height V-Nose Enclosed Trailer

- 12,000 GVWR, 16″ Radials, Electric Brakes

- 2 lb. SPF Insulation Package

- Double Rear Doors, Side Door

- Two Closable Vents In Generator Room

- Hose Door

- High Efficiency Diesel Furnace, 13,600 BTU

- Digital Thermostat

- 120V Fluorescent Lighting Package

- Full Size Spare Tire

- Stone Guard

Safety Details

- 3/4 HP Continuous Flow Supplied Air Pump

- 3/8″ 100 Foot Supplied Air Hose

- Full Face Mask Supplied Air Respirator

- Half Mask Respirator w/Organic Vapor Cartridges

- Eyewash Station

- First Aid Kit

- Disposable Spray Suits

- Nitrile Gloves, Box of 100

- Spill Kit, 6 Gallon

- 10 lb. ABC Approved Fire Extinguisher

- MSDS & Manual Station

Image Gallery

Equipment Options

1By replacing a standard 40 kw generator with a 22 kw generator, the system’s fuel needs are greatly reduced. Savings are an estimate only. Actual savings may vary.

2All Graco Reactors carrying the “XP” designation in the model name are capable of processing 1:1 ratio foam insulation and protective coatings. (Example: Reactor 3 E-XP2 or Reactor 2 H-XP3)

3Flow Meters – The Reactor Ratio Assurance System is designed to provide ratio detection so your job is being applied on-ratio and within tolerance. (Included on Reactor elite models E-30, H-30, H-40 and H-50)

4The Xtreme-Wrap Scuff Guard is more durable and robust than typical guards, meaning it will protect and prolong the life of your hose.

5Also available with a 35 CFM integrated Hydrovane rotary compressor.